General Motors has always been one of the big-dogs of the performance industry, and the Chevrolet division has always been at the forefront of what it meant to be a performance-car manufacturer. Even going back to the 1950s, when Chevrolet organized the creation of the fabled Black Widow 1957 Chevy, they were challenging all comers.

Need GM parts? Call our Parts/Accessories Dept. at 630-898-9630 or visit our website.

It was only a few years after that iconic Tri-Five was built that Chevy was essentially forced to stop support of sanctioned racing. There were several contributing factors to the public boycott, and the sale of performance parts was nearly brought to a complete halt.

Another one of our articles from 2010, “The History of GM Factory-Backed Racing: On, Off, and On Again” talks about the full history of Chevrolet racing and their relationship with the performance industry. The biggest contributing factor to the ban – according to that article – was the sheer size and sales volume of General Motors vehicles. By 1962 and 1963, GM sales consisted of around 53 percent of the entire auto market, and the powers that be were getting worried about being forced by the U.S. government to split up. The answer: drop the performance arm. Of course, that was just publicly. If you knew what to look for, you could still get the good stuff from your local Chevy dealer.

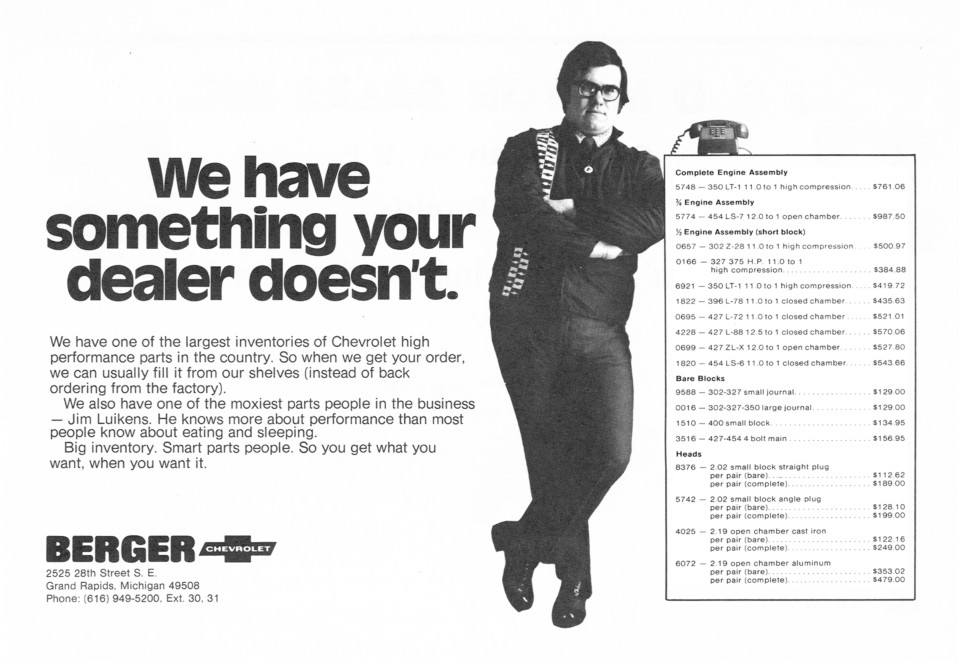

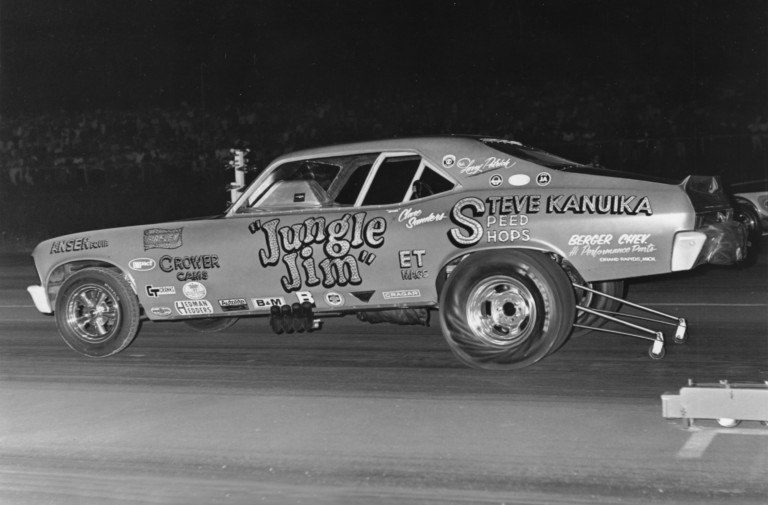

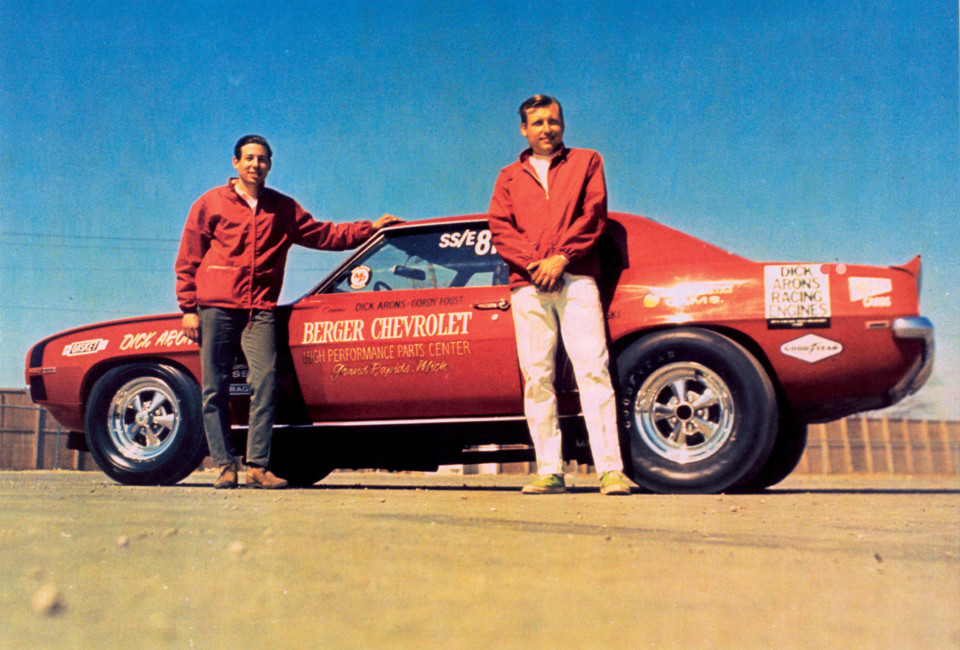

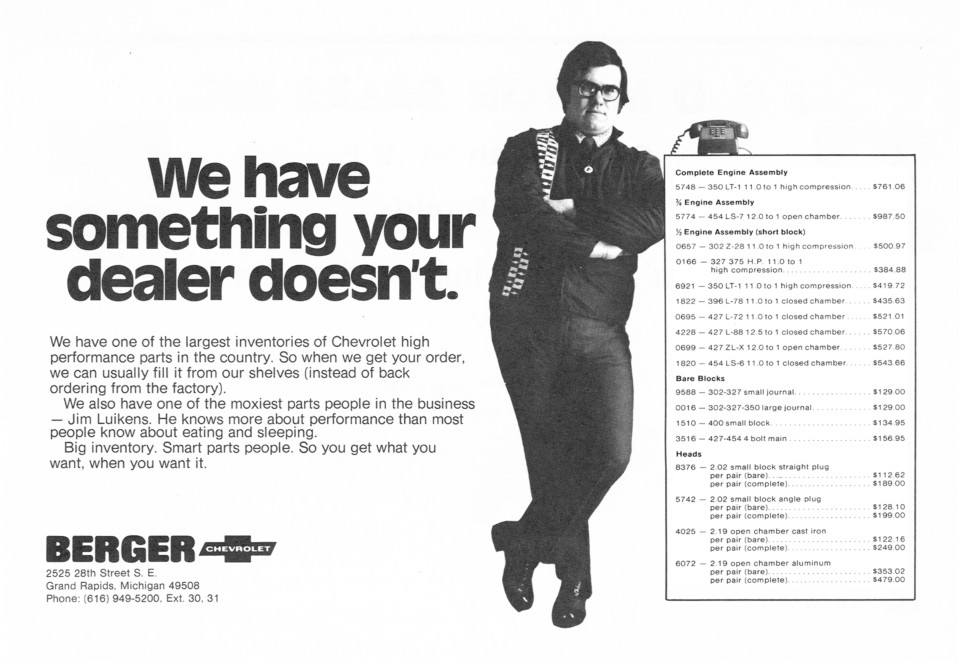

Jim Luikens and Berger Chevrolet were “performance central” for many speed junkies.

It’s well known now that Chevrolet never really stopped making or selling performance parts. They simply weren’t publicly promoting them. Back then, Chevrolet developed a system for hiding its performance parts in plain sight – the standard parts catalog. Although no company wide announcement was made about the “hidden” parts, a select few took matters into their own hands, cracked the code, and figured out how to order those parts. One of those intrepid sleuths was Jim Luikens, lifelong resident of Grand Rapid, Michigan, and the former parts manager for Berger Chevrolet from 1970 to 1975.

“I started at Berger in November of 1968. We had a department manager, and I was his assistant. Then, in June of ’70, I was pushed up to manager, and I was there until 1975. Not only did we have Chevrolet parts, but we also had the ‘Cadillacs of speed equipment’: Mr. Gasket, Holley, and all that stuff. We knew the GM parts, and all the other factories as well,” said Jim.

We thought at the time we were doing something special, but we had no idea how special it was and that it would stand the test of time – Jim Luikens

“We weren’t facing opposition from Chevy about selling the parts. But they did not help us find things. When we figured it out though, then they finally helped us,” he said. All of the parts that Chevrolet had were available through the parts book, and the parts book was where they hid everything. In a way, they were hiding the parts in plain sight, but you had to know what you were looking for. “At the time, we thought we were doing something special, but we had no idea how special it was and that it would stand the test of time,” Jim recalled.

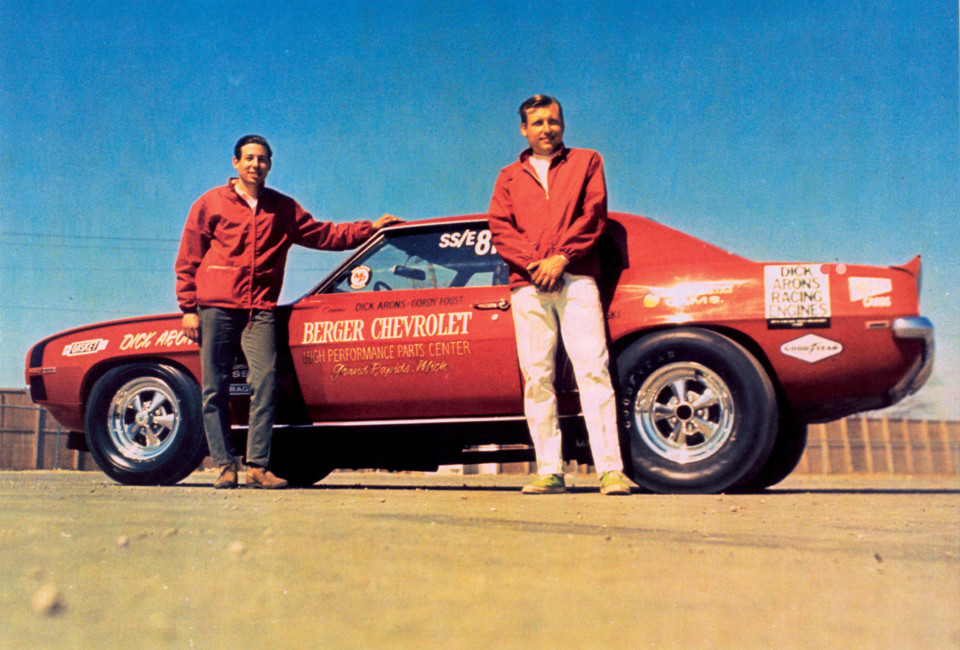

Berger Chevrolet back in the day.

The Key

“There were no parts available that were not in the parts book. After a while, I figured out the method they used to hide them. I would take the parts books home on the weekends to study them,” Jim said with a chuckle.

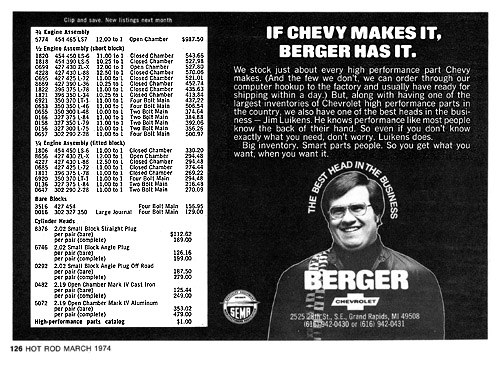

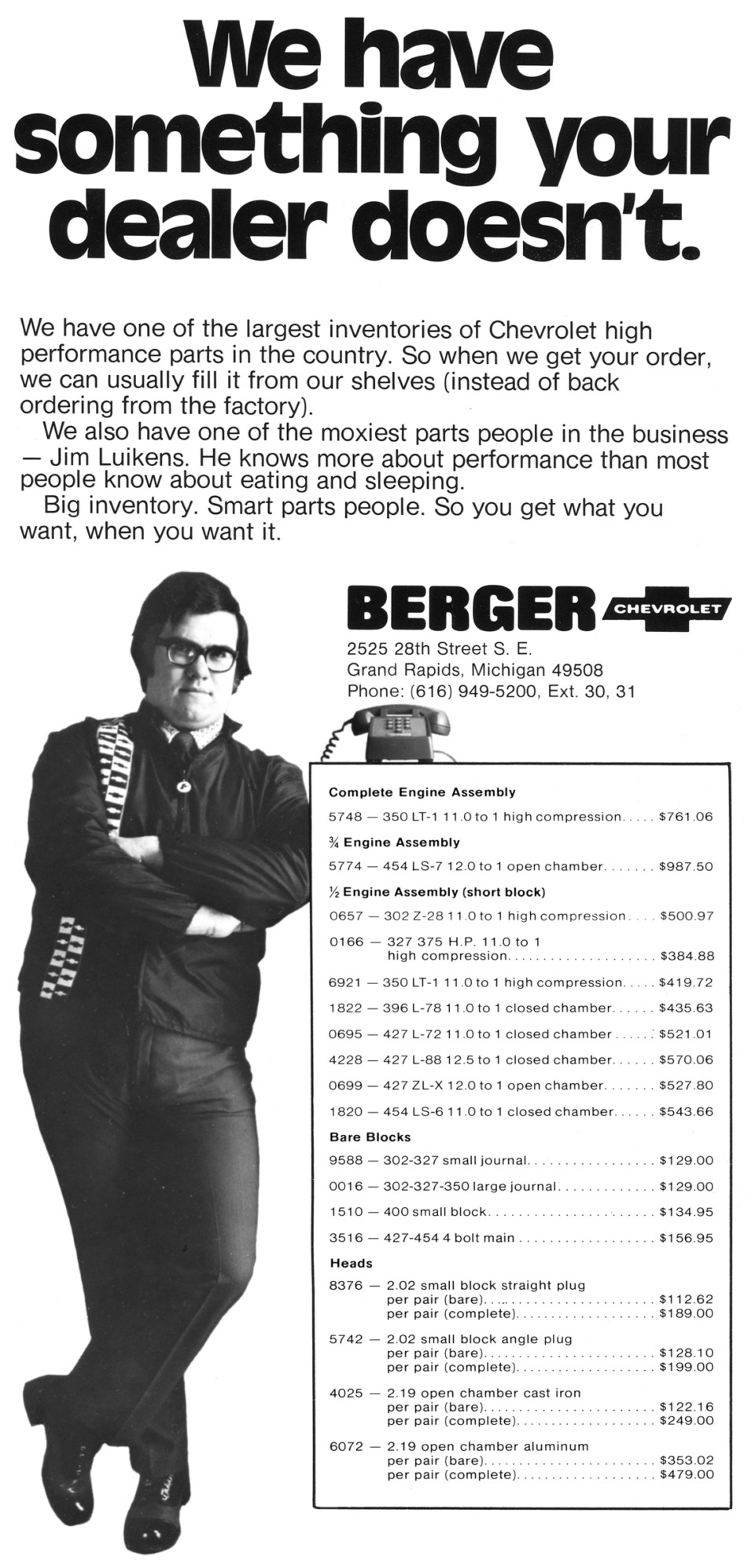

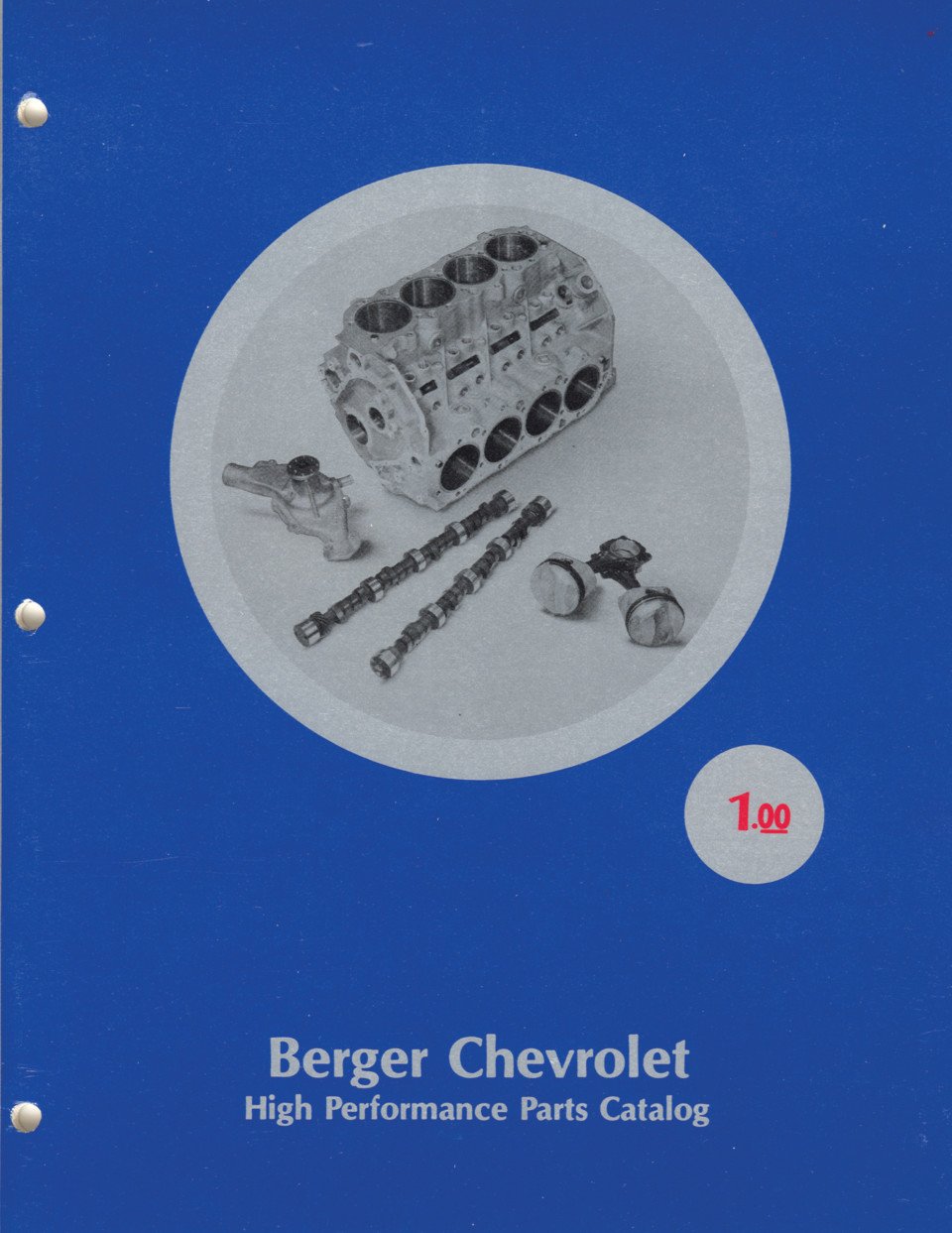

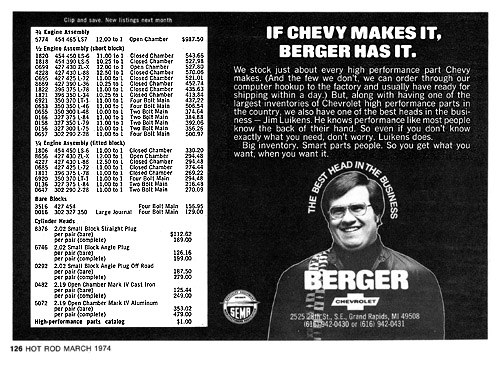

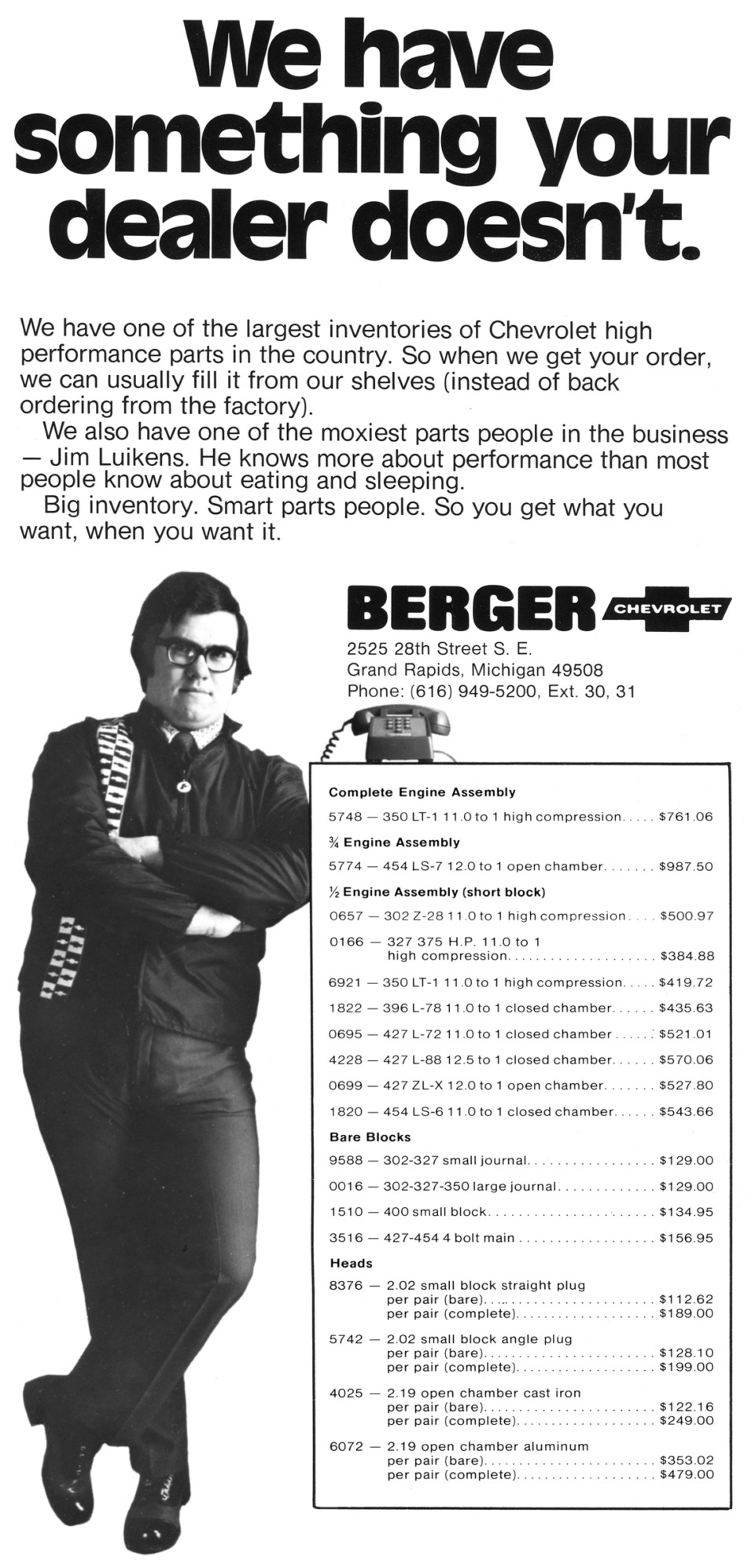

A snapshot of Berger Chevrolet parts from back in the day. Are you drooling yet?

“I was driven and motivated – and a little crazy, really. I looked at what they were doing with part numbers. The parts would be there, but there would be very deceiving descriptions, or even coded descriptions. For instance, one part that comes to mind is the 36-gallon Corvette gas tank. All parts were listed in this book by group, and numbered from 0 to 8,000. The gas tanks were in the 3,000 section, and if you looked there for the 36-gallon Corvette gas tank, you’d never find it. The 36-gallon tank was actually hidden in the gas cap group. They called it a cap and tank assembly,” Jim stated.

Don’t those prices just make you sick?

Finding parts was never an exact science though, and there was a lot of trial and error involved in cracking the code. “Sometimes I would order something with the dumbest name and get exactly what I ordered,” Jim said. He would look at the item’s description and think that it sounded too weird to be right, so he would order it just to find out. Most times, he would get just what he ordered. “Other times, I would order a part and get a miraculous part that was better than I could have imagined. I basically worked backwards from the description to figure out the item.” Part of what made Jim so successful in getting these parts was the third-generation Berger that was running the dealership at the time, R. Dale Berger. “He was very accommodating,” Jim stated.

Jim explained how confusing the catalog could be. “Back then, the real deal in performance was the solid-lifter engines. If you wanted to order the Hi-performance 396-cylinder head, you had to know what to order. One part might say 396-cylinder head, and if that’s what you ordered, what you’d get was a bare 325-horse cast-iron cylinder head. The next line would say 396 with high-performance cylinder head. In that case, you would get the cylinder head for the 350 horsepower engine. The third line would say SPCL HP, and that would also have the special lifters and would be hidden in the special, high-performance nomenclature. Once I figured that out, I knew more about the nomenclature I was looking for. For instance, the camshaft for that engine would say 396 with HP, then 396 with SPCL HP, and the SPCL would have been the solid lifter cam for the 375 horsepower engine.”

Even though Chevrolet wasn’t publicly supporting racing, they still made the parts. People could still get them if they knew who to ask—Jim Luikens at Berger Chevrolet.

Another way Jim figured out which parts were the ‘hidden performance parts’, was by knowing which warehouse the parts came from. “Chevrolet had parts warehouses all over the country, and dealers would normally get their delivery from the closest warehouse. But, Chevrolet had a parts warehouse in West Virginia, and they kept the special stuff there,” he told us. If the parts were coming from the West Virginia warehouse instead of the Detroit warehouse, then he knew he was probably getting something special.

“Chevy, didn’t give us any crumbs to follow. They couldn’t. But, if you figured out where the crumbs were, then they would help. They would make sure that I got what I needed. Once they figured out that I was going to find it and I wasn’t going to be stopped, they were going to help me,” he avowed.

Success

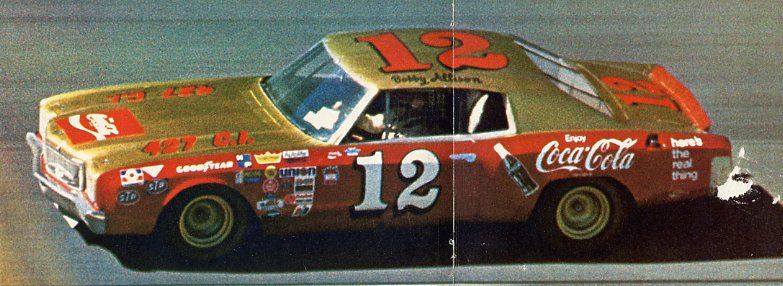

What R. Dale Berger recognized from the beginning, was that parts sales were the key to being successful. “He realized, for every guy who could afford a 427 Camaro, there were a 1,000 guys who needed a camshaft that were were running the local dragstrip on Friday nights,” Jim said.

“In 1967, there weren’t a lot of speed companies around. There were no aftermarket parts better than what GM was putting in the cars,” Jim explained, “That’s why we decided parts were the deal and we stocked them. People came from everywhere, because if you needed a special, tough-trotted crankshaft, you just couldn’t get one anywhere.”

The cover of the Berger parts catalog that Jim spent so much time reading.

Years later, the legacy lives on. We will always remember the efforts of people like Jim Luikens and R. Dale Berger, who made sure the passion for Chevrolet racing was kept alive. Jim left Berger Chevrolet in 1975 to work for Mr. Gasket. The insurance companies were starting to hand down tighter restrictions, and it was too expensive for young folks to buy and build their cars like they once had.

Even though it only lasted a few years, Jim’s time at Berger Chevrolet had a long-term impact on Chevrolet performance and the automotive industry. “As they say, I was living the dream every day,” Jim exalted.

Thanks for reading about Chevrolet Supported Racers Without Supporting Racers!